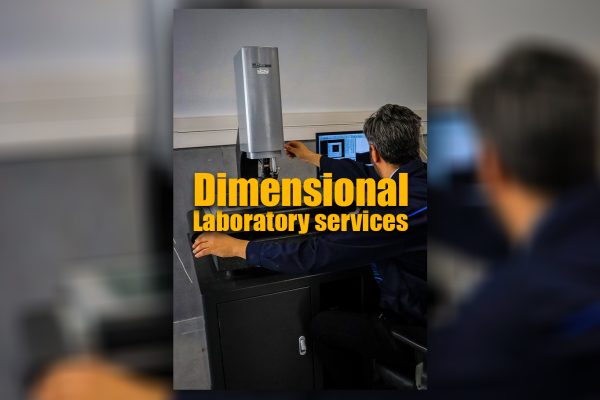

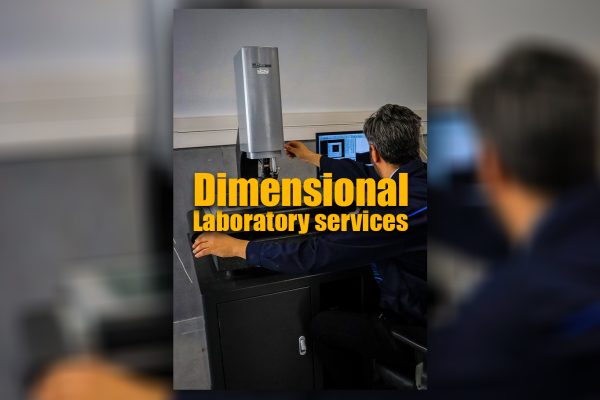

Laboratory

Parsayaran company has the most equipped quality control laboratories. Having a well-equipped and modern laboratory is one of the strengths of this company. Parsayaran quality control laboratory with experienced staff, along with modern laboratory equipment including Blow Molding devices and the most up-to-date equipment related to tank productions, applies quality control conditions continuously and effectively from the entry point to the delivery of the product.